Applications

As a leader in Laser Micromachining, Gateway Laser produces high-precision parts for a wide range of applications. Common applications include:

Other common applications for precision laser micromachining can include:

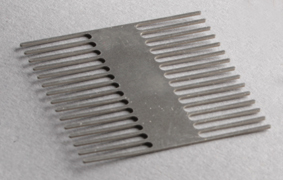

- Masks

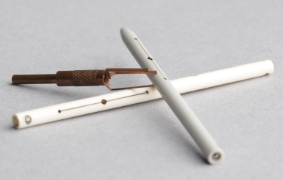

- Tubules

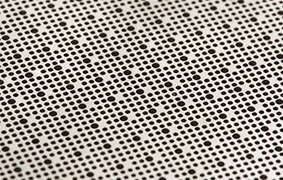

- Electronic components and parts including contacts, insulators, via drilling, silicon wafers and microchips

- Components for the automotive and aerospace industries including sensors, MEMs and OEMs