Gateway Laser Servies has 20+ laser systems including 7+ classes of lasers (Excimer, Femtosecond, Fiber Infrared, Green, UV, Welding/Texturing, and Marking). This allows us to cleanly process a wide range of materials including most polymers/plastics, metals, and ceramics. Since we focus entirely on small parts, each laser system is tailored for a specific job to ensure exceptional quality and quick turnarounds.

We’re constantly testing and adding new materials to our list of capabilities. We also source and stock materials for projects based on customer requirements. For more information regarding specific materials, email sales@gatewaylaser.com or complete the form below to request a quote.

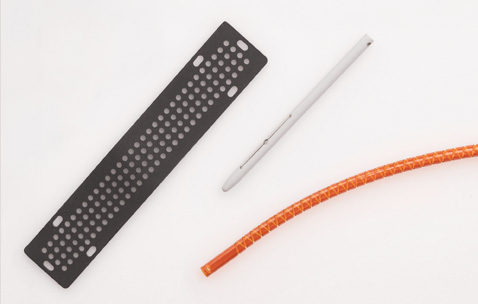

Polymers / Plastics

We process most polymers including thin films and multi-layered materials. Common polymers and polyimides we work with include Kapton, Mylar, PEEK, Pebax, and Kalrez along with various silicone and rubber materials. Our laser systems are designed to handle both tubular and flat stock polymers with micron-level precision. We process features as small as .0002” (5µm) with tolerances down +/- .00004” (1µm) depending on the thickness and type of polymer.

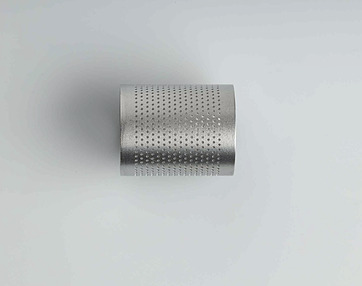

Metals & Foils

We process most metals including stainless steel, titanium, tantalum, brass, copper, foils, and other alloys. Our laser systems are designed to handle both tubular and flat stock metals (including thin foils) with micron-level precision. We process features as small as .001” (25µm) with tolerances down +/- .0002” (5µm) depending on the thickness and type of metal.

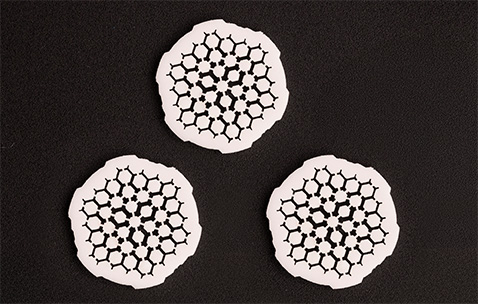

Ceramics

Laser micromachining is ideal for processing features on ceramic materials to avoid cracking and minimize HAZ (heat affected zones). Basic applications include producing micro-holes (micron-level holes) and/or complex geometries on wafers. We process features as small as .001” (25µm) with tolerances down +/- .0002” (5µm) depending on the thickness and type of ceramic.

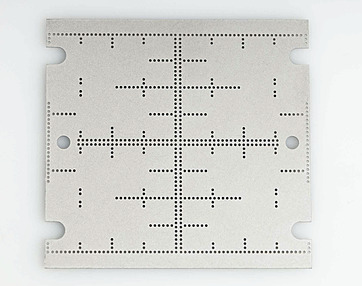

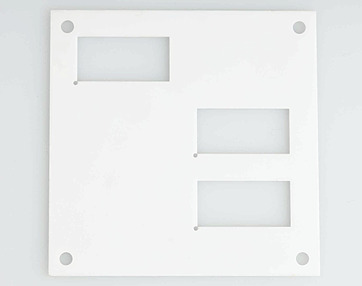

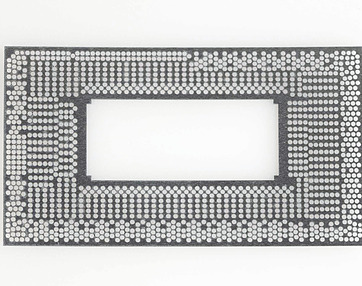

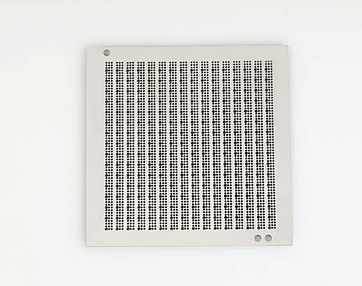

Our Work Examples

Click on image for additional information including feature size and material (please note parts are significantly magnified)